Jumao Oxygen Generator For CentralOxygen Supply System

Parameter

Voltage :380V/50Hz Oxygen Concentration:≥90% Max.Particle ф0.0lμm Min.Oil :0.001ppm

| Model | Oxygen 0utput (Nm³/h) |

Compressor | Skid-mounted (cm³) |

All-in G.W (Kg) |

System Power(Kw) |

Operating Mode |

Discharge Mode |

||

| Size (cm³) | Weight (KG) | Power (Kw) | |||||||

| JM-OST05 | 5 m³/h | 65*65*89 | 175 | 7.5 | 280*150*210 | 1950 | 9 | Automatic | Automatic+ Manual |

| JM-OST10 | 10 m³/h | 85*79*126 | 341 | 15 | 245*165*240 | 2200 | 17 | Automatic | Automatic+ Manual |

| JM-OST15 | 15 m³/h | 122*93*131 | 436 | 22 | 250*151*250 | 2700 | 24.5 | Automatic | Automatic+ Manual |

| JM-OST20 | 20 m³/h | 143*95*120 | 559 | 30 | 300*190*225 | 3200 | 32.5 | Automatic | Automatic+ Manual |

| JM-OST30 | 30 m³/h | 143*95*141 | 660 | 37 | 365*215*225 | 4800 | 40 | Automatic | Automatic+ Manual |

| JM-OST50 | 50 m³/h | 195*106*160 | 1220-1285 | 55-75 | 520*210*250 | 6200 | 59-79 | Automatic | Automatic+ Manual |

| JM-OST60 | 60 m³/h | 195*106*160 | 1285 | 75 | 520*210*250 | 7100 | 79.5 | Automatic | Automatic+ Manual |

| JM-OST80 | 80 m³/h | 226*106*160 | 1570-1870 | 90-110 | 260*245*355 +245*200*355 |

9000 | 96.8-116.8 | Automatic | Automatic+ Manual |

| JM-OST100 | 100 m³/h | 226*106*160 | 1870 | 110-132 | 947*330*350 | 11000 | 117.3-139.3 | Automatic | Automatic+ Manual |

Features

- Unique double tower structure, Efficient and stable oxygen production: 1m³/h ~ 120m³/h

- Unique molecular sieve fillingtechnology: high efficiency and longer service life

- UOP molecularsieve, High oxygen concentration: ≥90%

- Siemens PLC automatic control: Intelligent regulation, Multiple alarms

- Oxygen analyzer configuration: Real-time monitoring, Safe oxygen use

- Multi-grade ultra-precision filter: Remove oil and dust, Prolong the service life

- Medical grade stainless steel pipe: Durable, Reliable, Clean and Pollution-free

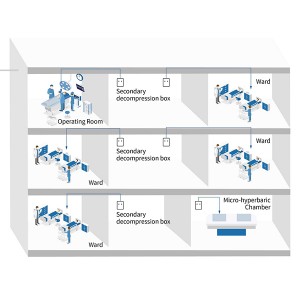

- Large split oxygen generation system, designed for hospitals

- Integrated PSA technology, with high performance configuration, makes the whole system stable and reliable

- Low energy consumption, less cost, strong adapt ability, rapid oxygen production

- Fully automatic operation, integrated PLC control, high inteligent automatic control, with the highest safety anareliability, continuous 24-hour uninterrupted automatic operation, meeting the oxygen supply requirements ofthe hospital in emergencies and peak periods of oxygen consumption

- Touch screen display, shows the oxygen purity, flow, pressure and other operating parameters

- Adjustable oxygen output pressure to meet the needs of various oxygen using equipment in the hospital

- Remote monitor the concentration, flow and pressure

- Diagnosis,alarming system,ensure safety oxygen use

Product Display